The company's core business is the R&D, manufacturing and sales of fully automated machinery and equipment, intelligent packaging units and intelligent coil logistics systems.

With the development and progress of the logistics industry, various advanced technologies and equipment are widely used in logistics transportation and cargo packaging. Among them, the fully automatic strapping machine, as an efficient and fast packaging equipment, is gradually being widely used in the logistics industry.

The fully automatic strapping machine is an automated packaging equipment that can quickly strap bulk items into neat packages to improve the efficiency and safety of logistics transportation. Compared with the traditional manual strapping method, the fully automatic strapping machine has the following advantages:

First, the fully automatic strapping machine is efficient and fast. Traditional manual strapping requires workers to spend a lot of time and energy to complete, while the fully automatic strapping machine only needs simple settings and operations to complete the strapping process. It can quickly strap bulk items into neat packages in an automated way, greatly improving the efficiency of logistics transportation.

Secondly, the fully automatic strapping machine is stable and reliable. Manual strapping is prone to loose baling, which makes the package loose or damaged during transportation. The fully automatic strapping machine can ensure the strength and firmness of each package through precise control and adjustment, improving the safety and stability of the goods.

In addition, the fully automatic strapping machine also has the characteristics of cost saving. Traditional manual strapping requires a lot of manpower and time to operate, while the fully automatic strapping machine only requires a small number of staff to monitor and maintain. Its high efficiency and stability can greatly reduce the waste of manpower and time, saving the cost of the enterprise.

In the logistics industry, the wide application of fully automatic strapping machines involves various links and fields. First, in the warehousing link, fully automatic strapping machines can quickly strap goods and improve the loading and unloading efficiency of warehouses. Secondly, in the transportation link, fully automatic strapping machines can ensure the safety and stability of goods and reduce damage and loss of goods during transportation. In addition, fully automatic strapping machines can also be used in logistics packaging, electronic product packaging and other fields to improve the efficiency and quality of packaging.

In short, as an efficient, fast, stable and reliable packaging equipment, fully automatic strapping machines are being widely used in the logistics industry. Its appearance has improved the efficiency and safety of logistics transportation and reduced the cost of enterprises. I believe that with the advancement of technology and the improvement of equipment, fully automatic strapping machines will play a more important role in the logistics industry and make greater contributions to the development of the logistics industry.

How to choose the right automatic baler head for your needs

How to choose the right labeling machine for your needs

Maintenance and care tips for logistics vehicles

Wide application of fully automatic strapping machines in the logistics industry

The purchase guide for the fully auto steel pipe stacking production and packaging unit to improving the production efficiency

How to choose the marking spray machine that suits your needs

Guidelines for Choosing Clipping Belt Machine to Improve Production Efficiency

Introduction to the types and functions of logistics vehicles

Logistics vehicles are an indispensable part of the modern logistics industry. They undertake important tasks such as cargo transport, distribution and warehousing. With the development of the logistics industry, the types of logistics vehicles are becoming more and more diversified; different types of logistics vehicles have different functions and characteristics. This article will introduce you to several common types of logistics vehicles and their functions.First, the lorry logistics vehicleLorry is the most common type of vehicle in logistics transport. According to different load capacity and size, lorries can be divided into small vans, medium-sized lorries and large lorries. Small vans are suitable for urban distribution and small-volume goods transport; medium-sized vans are suitable for short and medium-distance goods transport, and large vans are suitable for long-distance transport and large-volume goods distribution. The characteristics of lorries are strong loading capacity and wide adaptability, and they can be modified according to the needs, such as adding cold storage equipment and closed compartments, etc., to meet the transport needs of different types of goods.Second, cold chain logistics vehicleCold chain logistics vehicles are mainly used for transporting and distributing temperature-sensitive goods, such as food, medicine and cosmetics. Cold chain logistics vehicles control the temperature inside the vehicle through refrigerating equipment and insulated compartments to maintain the freshness and quality of the goods. Cold chain logistics trucks also have temperature recording and tracking functions, which can monitor the temperature changes of the goods in real time to ensure the safety of the goods during transport.Third. Container TruckContainer truck is a kind of logistics vehicle specially used for container transport. It adopts the standardised container design, can be used with the port container dock, to achieve rapid loading and unloading of goods and transshipment. Container trucks are suitable for long-distance cargo transport and international trade, with high efficiency and safety features. In addition, container trucks can also be required to carry out multiple container stacking transport, improving transport efficiency.Fourth, warehousing logistics vehicleWarehouse logistics trucks are mainly used for handling and stacking goods in the warehouse. They are usually equipped with forks and lifting devices, can be easily and quickly put the goods on the shelves or placed up. Warehouse logistics vehicles have flexibility, efficiency and safety features, and can improve the efficiency of goods handling in the warehouse, reduce human labour costs.Fifth, special logistics vehiclesSpecial logistics vehicle is a class of logistics vehicles designed according to specific needs. For example, chemical logistics vehicle for the transport of dangerous goods, equipped with special safety equipment and protective measures; trailer is a tractor that can be connected to the vehicle for long-distance cargo transport; handling trucks are suitable for large-scale cargo transport, such as machinery and equipment, construction materials. Special logistics vehicles have different functions and characteristics, and can meet the transport needs of specific industries and fields.To sum up, the types and functions of logistics trucks are diversified, and according to different needs and use scenarios, choosing the right logistics truck is crucial for improving logistics efficiency and reducing logistics costs. Therefore, when choosing a logistics vehicle, you need to consider factors such as the characteristics of the goods, transport distance, transport volume and safety requirements. We hope that this article can provide you with a preliminary understanding of the types and functions of logistics vehicles, and provide you with some reference and guidance for your logistics transport.Working principle and application of fully automatic steel pipe stacking production and packaging unit

With the continuous development of industrial automation, the fully automatic steel pipe stacking production and packaging unit has become an indispensable and important equipment in modern industrial production lines. This article will introduce the working principle and application of the fully automatic steel pipe stacking production and packaging unit in detail.1>. Working PrincipleThe fully automatic steel pipe stacking production and packaging unit is an efficient and precise mechanical equipment that realizes the palletizing and packaging of steel pipes through an automated control system. Its working principle mainly includes the following steps:The first step is steel pipe transportation: the steel pipe is sent to the working area of the palletizing unit through a conveyor belt or roller conveyor on the production line.The second step is palletizing: the manipulator or robot arm palletizes the steel pipe according to certain rules according to the preset program. The movement trajectory of the manipulator can be achieved through a pre-set path or a visual recognition system.The third step is packaging: after palletizing, the steel pipe is sent to the packaging unit and packaged by automated packaging equipment. The packaging method can be adjusted according to customer needs. Common packaging methods include wrapping film packaging, carton packaging, etc.The fourth step is out of the warehouse: the packaged steel pipe is sent to the out of the warehouse area and prepared for loading and transportation.2>. Application fieldsThe fully automatic steel pipe palletizing production and packaging unit is widely used in the field of steel pipe production and logistics. Its main applications include:1. Steel pipe production line: The fully automatic steel pipe palletizing production and packaging unit can realize the automatic palletizing and packaging of steel pipes, greatly improving production efficiency and quality stability. At the same time, it reduces manual operations, reduces labor costs, and improves the operating efficiency of the production line.2. Warehousing and logistics: The fully automatic steel pipe palletizing production and packaging unit can realize the fast and accurate palletizing and packaging of steel pipes, and improve the efficiency and accuracy of warehousing and logistics. At the same time, it can effectively save storage space and increase storage capacity.3. Logistics and transportation: The fully automatic steel pipe palletizing production and packaging unit can package steel pipes, enhance the stability and protection of steel pipes, and reduce damage and deformation during transportation. At the same time, it improves transportation efficiency, reduces manual operations, and reduces transportation costs.3>. Advantages and FeaturesCompared with traditional manual palletizing and packaging, the fully automatic steel pipe palletizing production and packaging unit has the following advantages and features:1. High efficiency: fully automated operation, improves production efficiency and reduces labor costs.2. Accuracy: The automated control system accurately controls the motion trajectory of the manipulator to ensure the accuracy of palletizing and packaging.3. Stability: Professional packaging equipment is used to ensure the stability and safety of steel pipes during transportation.4. Flexibility: It can be adjusted and customized according to customer needs to meet the palletizing and packaging needs of steel pipes of different specifications and sizes.Summary:The fully automatic steel pipe palletizing production and packaging unit is an indispensable and important equipment in modern industrial production lines. Its efficient and precise working principle and wide application field make it an important tool to improve production efficiency, reduce costs and improve quality. With the continuous development of industrial automation technology, it is believed that the fully automatic steel pipe palletizing production and packaging unit will have a broader application prospect in the future.Innovative Technology and Trend of Clipping Belt Machine

As an important mechanical equipment, clipping belt machine is widely used in all walks of life in the dismantling work. With the continuous progress of science and technology and the continuous development of society, the technology of clipping belt machine is also constantly innovating and improving, showing a series of development trends. In this article, we will discuss the innovation and development trend of strip removal machine technology from various aspects.First of all, automation is a significant feature of belt-clipping machine technology. Traditional belt removal usually requires manual operation, which is time-consuming and inefficient. The innovation of modern belt removal machine technology makes the belt removal machine can realise automatic operation, which greatly improves the working efficiency. For example, the current market has appeared with some automated function of the belt removal machine, which can be controlled through the programme to complete the dismantling work, without manual intervention. This innovation makes it work faster and more efficient, and greatly saves the human cost.Secondly, intelligence is another development trend of belt removal machine technology. With the continuous progress of artificial intelligence technology, the belt removal machine also began to introduce intelligent functions. For example, some new strip removal machines are equipped with intelligent sensing equipment, which can automatically adjust the working parameters according to the size, shape and material of the disassembled object to improve the accuracy and effect of the operation. In addition, some belt removal machines also have intelligent recognition function, can automatically identify the type and structure of the disassembled object, to provide targeted belt removal programme, making it more convenient and efficient to complete the disassembly task. These intelligent innovations make the belt removal machine more intelligent, convenient, and improve the efficiency and quality of work.Furthermore, environmental protection is another important development direction of the technology of belt removal machine. As global environmental problems become more and more prominent, the impact of the dismantling work on the environment is also getting more and more attention. Traditional belt removal work usually produces a large amount of waste and pollutants, bringing serious impact on the environment. However, the innovation of modern belt removal machine technology makes the disassembly work more environmentally friendly. For example, some new belt unwinding machines adopt environmentally friendly materials and designs, which can minimise the generation of waste and pollution to the environment. In addition, some belt splitters also have the function of waste recycling and resource utilisation, which can classify, treat and reuse the waste generated in the process of disassembling and assembling, and realise the recycling of resources. These environmentally friendly innovations make the belt removal machine technology more in line with the requirements of sustainable development, and make a positive contribution to the protection of the environment.Finally, multifunctionality is another development trend of the belt splitter technology. The traditional belt removal machine usually can only complete specific disassembly work, single function. And the innovation of modern tape removal machine technology makes the tape removal machine has more functions. For example, some of the new belt splitter can not only carry out disassembly work, but also can carry out cleaning, polishing, repair and other work, to provide a full range of disassembly services. In addition, some belt splitters also have remote operation and networking function, which can be remotely monitored and controlled through the Internet to achieve remote operation and management. These multifunctional innovations make the belt removal machine more flexible and diverse, meeting the different needs of users.To sum up, the innovation and development trend of belt removal machine technology is mainly reflected in automation, intelligence, environmental protection and multifunctionality. With the continuous progress of science and technology and the continuous development of society, the technology of belt removal machine will continue to usher in more innovations and breakthroughs. It is believed that in the near future, the belt removal machine will become an indispensable and important tool for all walks of life, to improve work efficiency and protect the environment to make greater contributions.Maintenance and care tips for logistics vehicles

With the development of the logistics industry, logistics vehicles as an important tool for logistics transportation, bear the heavy responsibility of cargo transportation. However, due to the high intensity of work, complex road conditions and other reasons, the maintenance and repair of logistics vehicles is particularly important. In this article, we will introduce some of the logistics vehicle maintenance and skills to help owners to improve the service life and safety of the vehicle.First of all, regular routine inspection is the basis of logistics vehicle maintenance. Vehicle owners should every once in a while, the appearance of the logistics vehicle and internal parts of the inspection. In terms of appearance, check whether the body is scratched, damaged, etc., especially pay attention to whether the vehicle's lights are normal. For internal parts, check the engine, braking system, suspension system and other key parts to make sure they are running properly. In addition, oil, filters and other wear parts should be replaced regularly to keep the engine in good condition.Secondly, the correct driving and operation of logistics vehicles is also an important part of maintenance. Logistics vehicles in the transportation process, often need to go through complex roads and poor weather conditions, so drivers should have good driving habits and skills. First of all, to comply with traffic rules, reasonable driving, avoid speeding, harsh braking and other behavior. Secondly, pay attention to the road conditions during driving to avoid damage to the vehicle caused by unexpected conditions. Finally, according to the vehicle load, adjust the air pressure and tire wear to ensure the stability and safety of the vehicle.In addition, regular maintenance and repair of logistics vehicles should not be ignored. Logistics vehicles will inevitably have some wear and tear and malfunction during a long time of work. Therefore, vehicle owners should regularly send their vehicles to regular repair stores for maintenance and repair. Maintenance includes replacing oil and filters, checking the brake system, fuel system and so on. Repair, on the other hand, is to deal with the malfunction of the vehicle and repair it in time to avoid the expansion of the malfunction. At the same time, the owner should also regularly wash the vehicle to keep the body clean and shiny to prevent corrosion and damage.Finally, the maintenance and repair of logistics vehicles also need the joint efforts of the owner and driver. Vehicle owners can strengthen the training and education of drivers to improve their awareness of logistics vehicle maintenance and repair. Drivers should strengthen the vehicle's daily inspection and maintenance, timely detection and treatment of problems. Only the joint efforts of owners and drivers can ensure the safety and stable operation of logistics vehicles.In summary, the maintenance and repair skills of logistics vehicles are vital to ensure the normal operation and safety of the vehicle. Vehicle owners should conduct regular routine inspections, drive and operate the logistics vehicle correctly, and maintain and repair the vehicle regularly. At the same time, vehicle owners and drivers should work together to raise the importance of logistics vehicle maintenance and repair. Only in this way can we ensure the good condition of logistics vehicles and provide strong support for the development of the logistics industry.The important role of labeling machines in product packaging

In modern society, product packaging not only protects goods, but also is an important means of promoting and marketing goods. As one of the key equipment on the packaging production line, labeling machines play an important role that cannot be ignored. This article will explore the important role of labeling machines in product packaging from different angles.First, labeling machines can improve packaging efficiency. In the traditional packaging process, labeling is a time-consuming and error-prone task. The emergence of labeling machines has greatly improved packaging efficiency. Labeling machines can accurately attach labels to products at a very fast speed, and have the function of automatic detection and correction, which greatly reduces the error rate of labeling. This not only saves labor costs, but also improves production efficiency, enabling companies to better meet market demand.Secondly, labeling machines can enhance product image. Product packaging design is an important part of the company's brand image. The labeling machine can attach labels to products and effectively convey the company's brand image and promotional information. The text, pattern and color on the label can directly affect consumers' impression and cognition of the product. The labeling machine can ensure the position and fit of the label, making the product packaging more beautiful and generous, and enhancing the competitiveness of the product.In addition, labeling machines can also improve the safety of packaging. In some industries, such as food and medicine, the safety and quality of products are the most concerned issues for consumers. Labeling machines can stick labels on products, effectively prevent labels from falling and changing, and ensure the integrity and safety of product packaging. Labeling machines can also apply some security labeling technologies, such as anti-counterfeiting labels, traceability labels, etc., to improve the safety and traceability of products and increase consumers' trust and satisfaction with products.Finally, labeling machines also have flexible and diverse functions. Modern enterprises have various needs for product packaging, and labeling machines can be adjusted and changed according to different needs. Not only can labels be applied to products of different shapes and sizes, but also different types of labels can be applied, such as barcodes, QR codes, RFID, etc. Labeling machines can also implement a variety of labeling methods, such as top labeling, side labeling, circumferential labeling, etc., to meet the packaging needs of different products.In summary, labeling machines play an indispensable role in product packaging. It can improve packaging efficiency, enhance product image, increase packaging safety, and also have flexible and diverse functions. With the continuous development of science and technology, the performance and functions of labeling machines are also constantly improving, bringing greater convenience and benefits to the company's packaging production line. I believe that as time goes by, labeling machines will play a more important role in product packaging and help companies achieve better development.Working principle and application of automatic strapping machine head

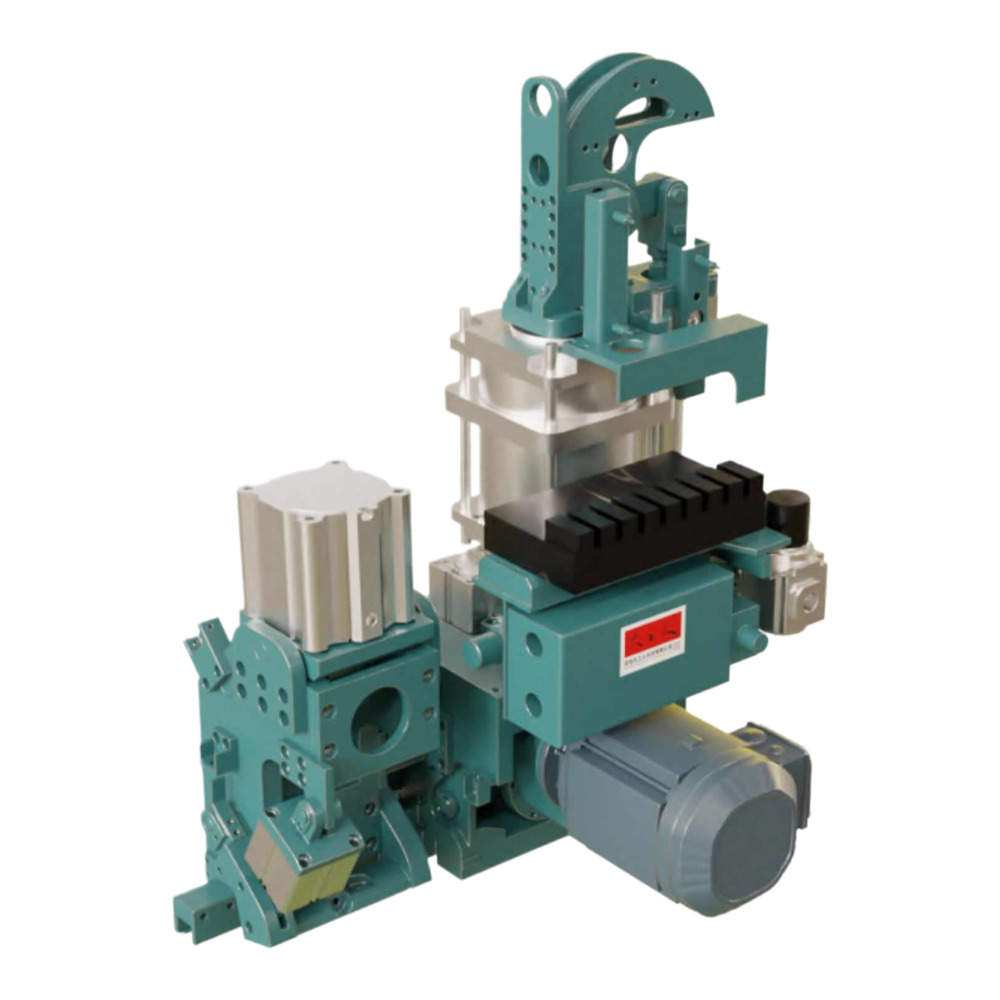

In recent years, with the rapid development of the logistics industry, packaging and strapping have become an important part of the cargo packaging and transportation process for many companies. In order to improve packaging efficiency and reduce labor costs, automatic strapping machine heads emerged as the times require. This article will introduce the working principle of the automatic strapping machine head and its application in various industries. The automatic strapping machine head, as the name suggests, is a device that can automatically complete the strapping operation. It consists of an electronic control system, mechanical structure and sensors. Through precise control, it can accurately complete the task of packaging and strapping. The working principle of the automatic strapping machine head mainly includes the following steps: First, place the goods to be packed on the working platform of the strapping machine head. Then, set the packaging parameters, such as the intensity of strapping, the number of strapping times, etc. through the touch screen or remote control. Next, the automatic strapping head will automatically adjust the length and tension of the strapping according to the set parameters, and wrap the strapping belt around the goods. Finally, the packing belt is cut and the packing operation is completed.The application of automatic strapping machine head is very wide. First, it is widely used in the logistics industry. During the packaging and transportation of goods, the automatic strapping machine head can improve packaging efficiency, reduce manual operations, and reduce labor costs. Secondly, automatic strapping machine heads are also used in the food processing industry. During food processing, the automatic strapping machine head can package food into a uniform shape and size, improving the aesthetics and hygiene of the packaging. In addition, automatic strapping machine heads are also widely used in textile, furniture, electronics and other industries to improve product packaging quality and efficiency.In addition to increasing efficiency and reducing costs, automatic strapping machine heads offer several other advantages. First, it can ensure the stability and security of packaging. By automatically adjusting the tension and length of the strapping, the automatic strapping machine head ensures that the goods will not become loose or damaged during transportation. Secondly, the automatic strapping machine head can also reduce errors and labor intensity caused by manual operations, and improve work efficiency and working environment.However, automatic strapping machine heads also have some limitations. First of all, its price is relatively high and requires a certain investment cost. Secondly, for some goods with special shapes or sizes, the automatic strapping machine head may not be applicable. In addition, the automatic strapping machine head also requires certain technical support in terms of maintenance and upkeep.In general, the automatic strapping machine head has become an indispensable piece of equipment in the modern logistics and packaging industry due to its efficiency, convenience and reliability. Its working principle is simple and clear, and its application range is wide. In the future, with the continuous advancement of technology and the expansion of application fields, the automatic strapping machine head is expected to demonstrate its advantages and potential in more fields.Marking spray machine maintenance and maintenance skills

The marking spray machine is a commonly used spraying equipment and is widely used in construction, automobile, furniture and other industries. It has the characteristics of good spraying effect and high work efficiency, but during long-term use, some faults and problems will inevitably occur. In order to ensure the normal operation of the marking machine and extend its service life, we need to perform maintenance and upkeep. Next, let us introduce the maintenance and upkeep of the marking spray machine from a few key tips.First of all, it is very important to clean the marking spray machine regularly. The marking spray machine will produce a large amount of spraying waste during its operation. If not cleaned in time, these wastes will accumulate inside the machine, affecting the spraying effect and even causing malfunctions. Therefore, we need to regularly disassemble the marking spray machine and clean the spray head, nozzle, spray gun and other parts to ensure that they are unobstructed.Secondly, the coating of the marking spray machine should be of appropriate brand and quality. Low-quality paint can cause clogging of the marking spray machine, poor spraying results, or even damage to the machine. Therefore, when purchasing paint, we must choose brands with good reputation and guaranteed quality to avoid using inferior paint.In addition, the nozzles of the marking spray machine need to be replaced regularly. The nozzle is the core component of the marking spray machine and directly affects the spraying effect. Long-term use will cause the nozzle to wear, resulting in uneven spraying and poor spraying effect. Therefore, we should regularly check the wear of the nozzles and replace worn nozzles in time to ensure the quality of spraying.In addition, there are some details that need to be paid attention to when using the marking spray machine. First of all, the operator must be familiar with the instruction manual of the marking spray machine and use the machine correctly. Secondly, the electrical part of the marking spray machine must be waterproof and moisture-proof to avoid electrical failures. Thirdly, when the marking spray machine is not used for a long time, the paint should be emptied to avoid clogging the nozzle. Finally, the storage location of the marking spray machine should be dry and ventilated to prevent the machine from getting damp and rusting.To sum up, the maintenance and upkeep of the marking spray machine is an important part to ensure its normal operation and extend its service life. The marking spray machine can be effectively maintained through regular cleaning, selecting appropriate coatings, and replacing nozzles. At the same time, pay attention to the detailed operation of the marking spray machine to avoid machine failure and damage. Only by doing a good job in maintenance and upkeep can we make better use of the marking spray machine, improve work efficiency, and obtain better spraying results.How to choose the right automatic baler head for your needs

With the development of industrialization and logistics industry, baler as a kind of efficient packaging equipment has been widely used. As the core component of the baler, the selection of the quality and performance of the automatic baler head has a crucial impact on the operation effect and packaging quality of the baler. In this article, we will focus on how to choose the automatic baler head that suits your needs.First of all, we need to understand the basic principle and working mode of automatic baler head. Automatic baler head is mainly composed of motor, reducer, transmission device and baling hook. Its working principle is to drive the reducer through the motor, and then the transmission device drives the baling hook to complete the baling action. Therefore, the quality and performance of the baler head are directly related to the working efficiency and stability of the baler.Secondly, we should choose the right automatic baler head according to our needs. The first thing to consider is the carrying capacity of the baler head. Different industries have different packaging needs. Some industries need the baler head to carry more weight, while some industries are relatively small. Therefore, it is very important to choose the right baler head with suitable carrying capacity according to your packaging needs.then, the speed and stability of the baler head should be considered. As an efficient packaging equipment, the speed and stability of the baler has a direct impact on productivity and packaging quality. Therefore, it is very important to choose a fast and stable automatic baler head. At the same time, the noise and vibration of the baler head should also be considered to avoid unnecessary impact on the working environment and operators.In addition, the durability and ease of maintenance of the baler head should also be considered. Since the baler head is the core component of the baler, its durability and maintenance are directly related to the life span and operating cost of the baler. Therefore, it is very important to choose a durable and easy-to-maintain automatic baler head. You can assess the quality and ease of maintenance of the baler head by understanding the manufacturer's reputation and after-sales service.Finally, consider the price of the automatic baler head. Price is one of the factors that must be considered when choosing an automatic baler head. The price of different brands and models of baler heads varies greatly. When choosing, it is necessary to fully consider your own needs, but also to reasonably control the cost and choose the cost-effective automatic baler head.To summarize, choosing an automatic baler head that suits your needs is a process of comprehensively considering several factors. Only by choosing the automatic baler head with good quality, stable performance, convenient maintenance and reasonable price according to one's needs, can we ensure the working efficiency and packaging quality of the baler. I hope this article can provide some help to you in choosing automatic baler head.How to choose the right labeling machine for your needs

In modern industrial production, labeling machine is a very important equipment, which is widely used in various industries. Labeling machine can realize automatic labeling, improve production efficiency and reduce labor costs. However, there are many kinds of labeling machines on the market, with different functions, how to choose the labeling machine suitable for their needs has become a problem for many business owners.First of all, choose the labeling machine suitable for their needs need to consider the size and shape of the product. Different products have different labeling requirements, for example, cylindrical shape products need cylindrical bottle labeling machine, flat shape products need flat labeling machine. Therefore, before purchasing a labeling machine, business owners need to understand their product type and then choose the appropriate model of labeling machine.Secondly, consider the labeling speed and precision of the labeling machine. Labeling speed and precision is an important indicator of the performance of the labeling machine. For mass production enterprises, labeling speed is very important, can greatly improve production efficiency. For products with high labeling accuracy requirements, the choice of labeling machine with high precision can ensure the accuracy of labeling. Therefore, in the purchase of labeling machines, business owners need to choose the appropriate labeling speed and accuracy according to their own production needs.In addition, it is also necessary to consider the stability and reliability of the labeling machine. Labeling machine as a mechanical equipment, stability and reliability is its work to ensure normal operation. When buying a labeling machine, business owners need to choose a brand with a good reputation and credibility to ensure the quality and performance of the labeling machine. In addition, you also need to pay attention to the after-sales service and maintenance of the labeling machine, in order to solve equipment failures and problems in a timely manner.Finally, you also need to consider the operation and maintenance simplicity of the labeling machine. The operation and maintenance of the labeling machine is very important for the productivity and cost control of the enterprise. When buying labeling machines, business owners should choose simple operation, easy to start labeling machine, and understand its maintenance methods and cycles, in order to reduce downtime and maintenance costs.In summary, choosing the right labeling machine for your needs requires consideration of factors such as product size and shape, labeling speed and accuracy, stability and reliability, and ease of operation and maintenance. Business owners should make an informed choice when purchasing a labeling machine based on their production needs and budget to improve productivity, reduce costs and promote business development.Wide application of fully automatic strapping machines in the logistics industry

With the development and progress of the logistics industry, various advanced technologies and equipment are widely used in logistics transportation and cargo packaging. Among them, the fully automatic strapping machine, as an efficient and fast packaging equipment, is gradually being widely used in the logistics industry.The fully automatic strapping machine is an automated packaging equipment that can quickly strap bulk items into neat packages to improve the efficiency and safety of logistics transportation. Compared with the traditional manual strapping method, the fully automatic strapping machine has the following advantages:First, the fully automatic strapping machine is efficient and fast. Traditional manual strapping requires workers to spend a lot of time and energy to complete, while the fully automatic strapping machine only needs simple settings and operations to complete the strapping process. It can quickly strap bulk items into neat packages in an automated way, greatly improving the efficiency of logistics transportation.Secondly, the fully automatic strapping machine is stable and reliable. Manual strapping is prone to loose baling, which makes the package loose or damaged during transportation. The fully automatic strapping machine can ensure the strength and firmness of each package through precise control and adjustment, improving the safety and stability of the goods.In addition, the fully automatic strapping machine also has the characteristics of cost saving. Traditional manual strapping requires a lot of manpower and time to operate, while the fully automatic strapping machine only requires a small number of staff to monitor and maintain. Its high efficiency and stability can greatly reduce the waste of manpower and time, saving the cost of the enterprise.In the logistics industry, the wide application of fully automatic strapping machines involves various links and fields. First, in the warehousing link, fully automatic strapping machines can quickly strap goods and improve the loading and unloading efficiency of warehouses. Secondly, in the transportation link, fully automatic strapping machines can ensure the safety and stability of goods and reduce damage and loss of goods during transportation. In addition, fully automatic strapping machines can also be used in logistics packaging, electronic product packaging and other fields to improve the efficiency and quality of packaging.In short, as an efficient, fast, stable and reliable packaging equipment, fully automatic strapping machines are being widely used in the logistics industry. Its appearance has improved the efficiency and safety of logistics transportation and reduced the cost of enterprises. I believe that with the advancement of technology and the improvement of equipment, fully automatic strapping machines will play a more important role in the logistics industry and make greater contributions to the development of the logistics industry.Working principle and application fields of fully automatic strapping machine

In recent years, with the rapid development of the logistics industry, fully automatic strapping machines have become indispensable equipment. It is deeply loved by logistics companies and warehousing companies for its efficient and fast working methods. So, how does a fully automatic strapping machine work? What are its application areas? This article will answer them one by one for everyone.The working principle of the fully automatic strapping machine is mainly realized through the electrical control system and mechanical transmission system. It uses advanced sensor technology to automatically sense the volume and shape of items and automatically adjust according to set parameters. During the work process, the fully automatic strapping machine first pulls the strapping belt from the reel, then uses a mechanical device to wrap the strapping belt around the goods, then tightens and cuts it, and finally completes the strapping operation. The entire process requires no manual intervention, greatly improving work efficiency.Fully automatic strapping machines are widely used in various fields, especially the logistics industry and warehousing industry. In the logistics industry, fully automatic strapping machines can quickly and accurately strapping goods, improve the stability and safety of goods, and effectively reduce damage and loss of goods during transportation. In the warehousing industry, fully automatic strapping machines can quickly strapping large quantities of goods, saving labor costs and improving work efficiency. In addition, fully automatic strapping machines are also widely used in food processing, textile, furniture, building materials and other industries, providing strong support for enterprises.The application fields of fully automatic strapping machines are not limited to the above industries, but also include many other fields. For example, in the electronics industry, fully automatic strapping machines can strapping electronic products to protect the integrity and safety of the products; in the agricultural industry, fully automatic strapping machines can strapping crops to improve the quality and market competition of agricultural products. Power; in the housekeeping service industry, fully automatic strapping machines can strapping garbage, reduce the volume and pollution of garbage, protect the environment, etc.Generally speaking, the working principle of the fully automatic strapping machine is simple, efficient and has a wide range of applications. Through the application of automation technology, it improves work efficiency, reduces costs, and brings great convenience to the development of enterprises. In the future, with the continuous advancement of science and technology, fully automatic strapping machines will be increasingly used in various industries and make greater contributions to the development of society.Fully automatic steel pipe palletizing production and packaging units are widely used in the steel pipe industry

With the continuous development of science and technology, all walks of life are actively seeking automated and intelligent solutions, and the steel pipe industry is no exception. As an efficient and intelligent production equipment, the fully automatic steel pipe palletizing production and packaging unit has been widely used in the steel pipe industry.The fully automatic steel pipe palletizing production and packaging unit is a piece of equipment that integrates steel pipe palletizing, packaging and transportation. Compared with traditional manual operation, the fully automatic steel pipe palletizing production and packaging unit has higher production efficiency and more precise operation. It can automatically stack and package steel pipes according to set specifications and requirements, thus improving production efficiency and product quality.The application of fully automatic steel pipe palletizing production and packaging units not only improves production efficiency, but also greatly reduces labor costs and labor intensity. Traditional manual operations require a lot of manpower and are prone to problems caused by errors and fatigue. The fully automatic steel pipe palletizing production and packaging unit can realize fully automated operation, reducing the opportunity for manual intervention and effectively improving production efficiency and product quality.In addition to improving production efficiency and reducing costs, the fully automatic steel pipe palletizing production and packaging unit also has more advantages. First of all, it can realize diversified packaging methods and make flexible adjustments according to different products and customer needs. Secondly, it can realize the integrated operation of palletizing and packaging of steel pipes, reducing the costs and risks of logistics and warehousing links. In addition, the fully automatic steel pipe palletizing production and packaging unit also has an automated control system, which can monitor the production process and product quality in real time, improving the stability and reliability of production.The application of fully automatic steel pipe palletizing production and packaging units in the steel pipe industry has achieved remarkable results. It not only improves production efficiency and product quality, but also reduces labor costs and labor intensity. At the same time, it can also achieve diversified packaging methods and integrated operations, bringing more possibilities to the development of the steel pipe industry.In short, the widespread application of fully automatic steel pipe palletizing production and packaging units is an important step towards automation and intelligence in the steel pipe industry. It provides the steel pipe industry with more efficient, precise and reliable production solutions. It is believed that with the continuous advancement of science and technology, fully automatic steel pipe palletizing production and packaging units will play an increasingly important role in the steel pipe industry and make greater contributions to the development of the industry.How to choose the right automatic baler head for your needs

With the development of industrialization and logistics industry, baler as a kind of efficient packaging equipment has been widely used. As the core component of the baler, the selection of the quality and performance of the automatic baler head has a crucial impact on the operation effect and packaging quality of the baler. In this article, we will focus on how to choose the automatic baler head that suits your needs.First of all, we need to understand the basic principle and working mode of automatic baler head. Automatic baler head is mainly composed of motor, reducer, transmission device and baling hook. Its working principle is to drive the reducer through the motor, and then the transmission device drives the baling hook to complete the baling action. Therefore, the quality and performance of the baler head are directly related to the working efficiency and stability of the baler.Secondly, we should choose the right automatic baler head according to our needs. The first thing to consider is the carrying capacity of the baler head. Different industries have different packaging needs. Some industries need the baler head to carry more weight, while some industries are relatively small. Therefore, it is very important to choose the right baler head with suitable carrying capacity according to your packaging needs.then, the speed and stability of the baler head should be considered. As an efficient packaging equipment, the speed and stability of the baler has a direct impact on productivity and packaging quality. Therefore, it is very important to choose a fast and stable automatic baler head. At the same time, the noise and vibration of the baler head should also be considered to avoid unnecessary impact on the working environment and operators.In addition, the durability and ease of maintenance of the baler head should also be considered. Since the baler head is the core component of the baler, its durability and maintenance are directly related to the life span and operating cost of the baler. Therefore, it is very important to choose a durable and easy-to-maintain automatic baler head. You can assess the quality and ease of maintenance of the baler head by understanding the manufacturer's reputation and after-sales service.Finally, consider the price of the automatic baler head. Price is one of the factors that must be considered when choosing an automatic baler head. The price of different brands and models of baler heads varies greatly. When choosing, it is necessary to fully consider your own needs, but also to reasonably control the cost and choose the cost-effective automatic baler head.To summarize, choosing an automatic baler head that suits your needs is a process of comprehensively considering several factors. Only by choosing the automatic baler head with good quality, stable performance, convenient maintenance and reasonable price according to one's needs, can we ensure the working efficiency and packaging quality of the baler. I hope this article can provide some help to you in choosing automatic baler head.How to choose the right labeling machine for your needs

In modern industrial production, labeling machine is a very important equipment, which is widely used in various industries. Labeling machine can realize automatic labeling, improve production efficiency and reduce labor costs. However, there are many kinds of labeling machines on the market, with different functions, how to choose the labeling machine suitable for their needs has become a problem for many business owners.First of all, choose the labeling machine suitable for their needs need to consider the size and shape of the product. Different products have different labeling requirements, for example, cylindrical shape products need cylindrical bottle labeling machine, flat shape products need flat labeling machine. Therefore, before purchasing a labeling machine, business owners need to understand their product type and then choose the appropriate model of labeling machine.Secondly, consider the labeling speed and precision of the labeling machine. Labeling speed and precision is an important indicator of the performance of the labeling machine. For mass production enterprises, labeling speed is very important, can greatly improve production efficiency. For products with high labeling accuracy requirements, the choice of labeling machine with high precision can ensure the accuracy of labeling. Therefore, in the purchase of labeling machines, business owners need to choose the appropriate labeling speed and accuracy according to their own production needs.In addition, it is also necessary to consider the stability and reliability of the labeling machine. Labeling machine as a mechanical equipment, stability and reliability is its work to ensure normal operation. When buying a labeling machine, business owners need to choose a brand with a good reputation and credibility to ensure the quality and performance of the labeling machine. In addition, you also need to pay attention to the after-sales service and maintenance of the labeling machine, in order to solve equipment failures and problems in a timely manner.Finally, you also need to consider the operation and maintenance simplicity of the labeling machine. The operation and maintenance of the labeling machine is very important for the productivity and cost control of the enterprise. When buying labeling machines, business owners should choose simple operation, easy to start labeling machine, and understand its maintenance methods and cycles, in order to reduce downtime and maintenance costs.In summary, choosing the right labeling machine for your needs requires consideration of factors such as product size and shape, labeling speed and accuracy, stability and reliability, and ease of operation and maintenance. Business owners should make an informed choice when purchasing a labeling machine based on their production needs and budget to improve productivity, reduce costs and promote business development.Working principle and application of fully automatic steel pipe stacking production and packaging unit

With the continuous development of industrial automation, the fully automatic steel pipe stacking production and packaging unit has become an indispensable and important equipment in modern industrial production lines. This article will introduce the working principle and application of the fully automatic steel pipe stacking production and packaging unit in detail.1>. Working PrincipleThe fully automatic steel pipe stacking production and packaging unit is an efficient and precise mechanical equipment that realizes the palletizing and packaging of steel pipes through an automated control system. Its working principle mainly includes the following steps:The first step is steel pipe transportation: the steel pipe is sent to the working area of the palletizing unit through a conveyor belt or roller conveyor on the production line.The second step is palletizing: the manipulator or robot arm palletizes the steel pipe according to certain rules according to the preset program. The movement trajectory of the manipulator can be achieved through a pre-set path or a visual recognition system.The third step is packaging: after palletizing, the steel pipe is sent to the packaging unit and packaged by automated packaging equipment. The packaging method can be adjusted according to customer needs. Common packaging methods include wrapping film packaging, carton packaging, etc.The fourth step is out of the warehouse: the packaged steel pipe is sent to the out of the warehouse area and prepared for loading and transportation.2>. Application fieldsThe fully automatic steel pipe palletizing production and packaging unit is widely used in the field of steel pipe production and logistics. Its main applications include:1. Steel pipe production line: The fully automatic steel pipe palletizing production and packaging unit can realize the automatic palletizing and packaging of steel pipes, greatly improving production efficiency and quality stability. At the same time, it reduces manual operations, reduces labor costs, and improves the operating efficiency of the production line.2. Warehousing and logistics: The fully automatic steel pipe palletizing production and packaging unit can realize the fast and accurate palletizing and packaging of steel pipes, and improve the efficiency and accuracy of warehousing and logistics. At the same time, it can effectively save storage space and increase storage capacity.3. Logistics and transportation: The fully automatic steel pipe palletizing production and packaging unit can package steel pipes, enhance the stability and protection of steel pipes, and reduce damage and deformation during transportation. At the same time, it improves transportation efficiency, reduces manual operations, and reduces transportation costs.3>. Advantages and FeaturesCompared with traditional manual palletizing and packaging, the fully automatic steel pipe palletizing production and packaging unit has the following advantages and features:1. High efficiency: fully automated operation, improves production efficiency and reduces labor costs.2. Accuracy: The automated control system accurately controls the motion trajectory of the manipulator to ensure the accuracy of palletizing and packaging.3. Stability: Professional packaging equipment is used to ensure the stability and safety of steel pipes during transportation.4. Flexibility: It can be adjusted and customized according to customer needs to meet the palletizing and packaging needs of steel pipes of different specifications and sizes.Summary:The fully automatic steel pipe palletizing production and packaging unit is an indispensable and important equipment in modern industrial production lines. Its efficient and precise working principle and wide application field make it an important tool to improve production efficiency, reduce costs and improve quality. With the continuous development of industrial automation technology, it is believed that the fully automatic steel pipe palletizing production and packaging unit will have a broader application prospect in the future.Maintenance and care tips for logistics vehicles

With the development of the logistics industry, logistics vehicles as an important tool for logistics transportation, bear the heavy responsibility of cargo transportation. However, due to the high intensity of work, complex road conditions and other reasons, the maintenance and repair of logistics vehicles is particularly important. In this article, we will introduce some of the logistics vehicle maintenance and skills to help owners to improve the service life and safety of the vehicle.First of all, regular routine inspection is the basis of logistics vehicle maintenance. Vehicle owners should every once in a while, the appearance of the logistics vehicle and internal parts of the inspection. In terms of appearance, check whether the body is scratched, damaged, etc., especially pay attention to whether the vehicle's lights are normal. For internal parts, check the engine, braking system, suspension system and other key parts to make sure they are running properly. In addition, oil, filters and other wear parts should be replaced regularly to keep the engine in good condition.Secondly, the correct driving and operation of logistics vehicles is also an important part of maintenance. Logistics vehicles in the transportation process, often need to go through complex roads and poor weather conditions, so drivers should have good driving habits and skills. First of all, to comply with traffic rules, reasonable driving, avoid speeding, harsh braking and other behavior. Secondly, pay attention to the road conditions during driving to avoid damage to the vehicle caused by unexpected conditions. Finally, according to the vehicle load, adjust the air pressure and tire wear to ensure the stability and safety of the vehicle.In addition, regular maintenance and repair of logistics vehicles should not be ignored. Logistics vehicles will inevitably have some wear and tear and malfunction during a long time of work. Therefore, vehicle owners should regularly send their vehicles to regular repair stores for maintenance and repair. Maintenance includes replacing oil and filters, checking the brake system, fuel system and so on. Repair, on the other hand, is to deal with the malfunction of the vehicle and repair it in time to avoid the expansion of the malfunction. At the same time, the owner should also regularly wash the vehicle to keep the body clean and shiny to prevent corrosion and damage.Finally, the maintenance and repair of logistics vehicles also need the joint efforts of the owner and driver. Vehicle owners can strengthen the training and education of drivers to improve their awareness of logistics vehicle maintenance and repair. Drivers should strengthen the vehicle's daily inspection and maintenance, timely detection and treatment of problems. Only the joint efforts of owners and drivers can ensure the safety and stable operation of logistics vehicles.In summary, the maintenance and repair skills of logistics vehicles are vital to ensure the normal operation and safety of the vehicle. Vehicle owners should conduct regular routine inspections, drive and operate the logistics vehicle correctly, and maintain and repair the vehicle regularly. At the same time, vehicle owners and drivers should work together to raise the importance of logistics vehicle maintenance and repair. Only in this way can we ensure the good condition of logistics vehicles and provide strong support for the development of the logistics industry.The important role of labeling machines in product packaging

In modern society, product packaging not only protects goods, but also is an important means of promoting and marketing goods. As one of the key equipment on the packaging production line, labeling machines play an important role that cannot be ignored. This article will explore the important role of labeling machines in product packaging from different angles.First, labeling machines can improve packaging efficiency. In the traditional packaging process, labeling is a time-consuming and error-prone task. The emergence of labeling machines has greatly improved packaging efficiency. Labeling machines can accurately attach labels to products at a very fast speed, and have the function of automatic detection and correction, which greatly reduces the error rate of labeling. This not only saves labor costs, but also improves production efficiency, enabling companies to better meet market demand.Secondly, labeling machines can enhance product image. Product packaging design is an important part of the company's brand image. The labeling machine can attach labels to products and effectively convey the company's brand image and promotional information. The text, pattern and color on the label can directly affect consumers' impression and cognition of the product. The labeling machine can ensure the position and fit of the label, making the product packaging more beautiful and generous, and enhancing the competitiveness of the product.In addition, labeling machines can also improve the safety of packaging. In some industries, such as food and medicine, the safety and quality of products are the most concerned issues for consumers. Labeling machines can stick labels on products, effectively prevent labels from falling and changing, and ensure the integrity and safety of product packaging. Labeling machines can also apply some security labeling technologies, such as anti-counterfeiting labels, traceability labels, etc., to improve the safety and traceability of products and increase consumers' trust and satisfaction with products.Finally, labeling machines also have flexible and diverse functions. Modern enterprises have various needs for product packaging, and labeling machines can be adjusted and changed according to different needs. Not only can labels be applied to products of different shapes and sizes, but also different types of labels can be applied, such as barcodes, QR codes, RFID, etc. Labeling machines can also implement a variety of labeling methods, such as top labeling, side labeling, circumferential labeling, etc., to meet the packaging needs of different products.In summary, labeling machines play an indispensable role in product packaging. It can improve packaging efficiency, enhance product image, increase packaging safety, and also have flexible and diverse functions. With the continuous development of science and technology, the performance and functions of labeling machines are also constantly improving, bringing greater convenience and benefits to the company's packaging production line. I believe that as time goes by, labeling machines will play a more important role in product packaging and help companies achieve better development.Guangdong Province Enterprise of observing contract and valuing credit

Qualification

Top 100 quality suppliers in the steel industry